CIRC 2026 Rover Safety Requirements

Safety Inspection Process

The CIRC Rover Safety Requirements establish a minimum standard for Rover design, ensuring Teams minimize the risk of Rovers posing safety hazards or causing environmental damage. The construction and operation of all Rovers must comply with the CIRC Rover Safety Requirements, unless an exemption has been granted. Otherwise, they cannot participate in CIRC until all issues are resolved.

CIRC ensures Rovers meet the Safety Requirements by:

- Reviewing safety reports submitted by Teams ahead of competition, and

- Conducting a Rover physical inspection at CIRC Central before Teams compete.

Before Competition: Safety Report Process

- Teams must compile a safety documentation package to prove their Rover design meets the Safety Requirements and submit it to this Google Form by June 19, 2026.

- A single PDF must be submitted to the Google form that includes the content outlined in Requirement 7. The PDF report may contain direct links to datasheets or a shared folder containing all datasheets.

- There is no mandatory format for the documentation package. However, CIRC recommends following the format of the sample report.

- Teams are encouraged to submit partial (or full) documentation at any time before the deadline for feedback from the Safety Judges, especially if there are concerns about whether a design is compliant.

- Teams are also encouraged to contact [email protected] ahead of the deadline to ask rover safety-related questions.

- CIRC Safety Judges will review the documentation package and email feedback. If non-compliant, Teams must resubmit to the Google Form before a second, case-specific deadline.

- Teams have unlimited attempts to resubmit the documentation package, receive feedback, and make design changes before the competition.

- If a Team modifies their already-compliant Rover, they must submit an updated documentation package for safety re-evaluation.

- Teams may request exemptions to Rover Safety Requirements by emailing [email protected], highlighting the problematic requirement and proposed alternative.

- The proposed alternative should still meet the spirit of the requirement, if not the letter.

- Teams may request exemptions during any stage of the safety report process.

During Competition: Rover Physical Inspection Process

- All Rovers must pass a safety inspection after registration to compete in CIRC.

- The inspection verifies whether the constructed Rover matches the design in the submitted documentation package and if it is physically safe.

- A focus is placed on Requirement 6 and Parts of Requirement 3, which concern the physical aspects of a Rover.

- Teams shall request safety inspections in the designated Discord channel during competition (or in an alternative communication format if Discord is not used during the competition).

- Inspections at CIRC Central are available daily from 7:00 AM to 10:00 PM. Refer to the competition schedule for details.

- Judges will inspect Rovers as soon as possible. Wait times may reach 30 minutes during busy periods. Plan accordingly.

- Teams should have their Rovers in an operational state by the time of inspection.

- Teams may get Rover Modules (e.g., chassis/drivetrain, arm, science module) inspected separately.

- This helps Teams that do not need all Modules for their first task(s). A Team that does not need their arm immediately can get their Rover ready sooner by safetying the chassis and drivetrain first, then the arm later in the competition.

- Teams that have not had a Module inspected are not allowed to use it in competition tasks until it has been safetied - Judges are keeping track.

- After inspection:

- Teams that pass the physical safety inspection shall be given ribbons (one for each Module) that they must affix to their Rover as a visual indicator of compliance.

- Teams that do not pass must resolve any issues, then request a subsequent inspection.

- Teams must request reinspection if they make any safety-related changes to their Rover after passing the initial inspection.

- Safety Judges may conduct spot inspections on compliant Teams to ensure they have not made any safety-critical Rover alterations without requesting reinspection.

Definitions

CIRC-specific terms in the Safety Requirements are explained below.

- The word “must” indicates a mandatory requirement.

- The word “should” indicates a suggestion that may become a requirement in future competitions.

- A Circuit is one or more electricity-consuming devices (and the connections between them) that draw current from a single power source through a common circuit protection element.

- Regulators consume and provide power, with their input and outputs counting as at least one circuit each.

- The Rated Current Consumption of a component is the manufacturer-published value indicating the maximum safe amperage drawn by the device in normal continuous conditions, or for motors, their stall current.

- The Rated Current Capacity of a component is the amount of current that can be safely carried by wires, connectors, traces, or switches in a circuit on an ongoing/continuous basis. Transient, burst, or peak current limits are not acceptable for use when determining Rated Current Capacity.

- The Rated Supply Current of a component is the maximum acceptable amperage that a component, such as a battery, power supply, or regulator, can provide continuously. Transient, burst, or peak current limits are not acceptable for use when determining Rated Supply Current.

- The Interrupt Current Rating of circuit protection is the amperage above which it is designed to interrupt current flow.

- Circuit Protection is a fuse or electromechanical circuit breaker that reliably interrupts excessive current flow through a connected circuit. Software-based solutions are insufficient. Motor controllers, power regulators, or other devices with current-limiting capabilities are not sufficient for use as Circuit Protection. Self-resetting fuses are also insufficient.

- A Kill Switch is a physical switch mounted on a Rover that, when pressed down, interrupts power to all Rover systems until the switch is manually reset.

Rover Safety Requirements

- Rovers must not include any flammable, environmentally damaging, or otherwise hazardous liquids or gases, except:

- Within a permanently sealed component such as a battery;

- Commercially-available lubricants as required by mechanical assemblies, where care is taken to avoid overuse and contamination.

- Each Rover must be equipped with at least one kill switch.

- The pressable area of the kill switch must be at least 10 cm2 and red in colour. Levers or toggle switches are not acceptable.

- No other button on the Rover may be red.

- Kill switches must be mounted on the top of the Rover, with the button oriented toward the sky in the Rover’s normal driving orientation.

- A keep-out region must be maintained around the kill switch with a radius of 15cm. No components taller than the base of the kill switch may intrude on the keep-out region.

- Kill switches must not be obstructed by a cover or sleeve that extends above the pressable surface, and must be mounted such that they will not be obstructed by other components during Rover operation.

- The circuit, including the kill switch, must include appropriate circuit protection, and the Rated Current Capacity of the kill switch must exceed the Interrupt Current Rating of the circuit protection.

- The function of the kill switch must not depend on the integrity of any power source or computerized system. Indirect switching by relays or similar devices is permitted, provided that these are driven by the kill switch and reliably turn off when their control line is disconnected.

- The function of the kill switch must not depend on the integrity of any particular wiring connection; for example, physically tearing the kill switch off the Rover should produce the same effect as pressing it.

- If multiple kill switches are installed on the Rover, pressing any one must cut all power to the Rover.

- The function of the kill switch must not be disabled or bypassed by any means.

- The kill switch should be illuminated so that it can be seen at night.

- Rovers should have a remote motion stop for disabling a runaway Rover, such as a dead man’s switch on a lead, or a radio-frequency system that operates independently of the Rover communications system.

- Each battery must include or be installed with a single circuit protection element that protects all circuits supplied by the battery, and the battery itself.

- The Interrupt Current Rating of this protection must not exceed the lesser of:

- The Rated Current Capacity of the battery;

- 150% of the sum of the Rated Current Consumption of all connected circuits.

- This circuit protection must be installed as close as possible to the battery.

- Each Lithium battery must be protected by a battery management system that provides under-voltage lockout protection (UVLO) for each battery cell.

- The battery management system should provide cell voltage monitoring, over-current protection, and over-voltage protection.

- Batteries should be connected to their battery management systems when in use, and battery chargers should provide the same protection.

- All wiring and connecting hardware between the battery and circuit protection must be fully secured and insulated such that no reasonable impact, vibration, loose object, or liquid could possibly create an unprotected short circuit.

- If multiple batteries are used in parallel, each must have its own circuit protection element that satisfies the above requirements.

- Multiple batteries can be connected in series only if they feed a single circuit, and each battery has a battery management system with an individual cell UVLO.

- Custom-built batteries and BMSs are not allowed.

- Teams should use LiFePO4 (LFP) batteries, as they are not prone to thermal runaway.

- Teams using LFP batteries shall be given a 30% weight discount on their battery mass. For instance, a Team using a 2kg LFP battery shall have 0.3*2kg=0.6kg discount taken off their Rover’s total weight.

- The weight discount is not taken into account when evaluating the 70kg Rover weight limit.

- Teams wishing to take advantage of the LFP weight discount must notify judges and weigh their batteries at CIRC.

- Teams are responsible for the proper disposal of any compromised electrical components and/or batteries.

- The Interrupt Current Rating of this protection must not exceed the lesser of:

- Each circuit must include separate circuit protection.

- The Interrupt Current Rating of this protection must not exceed the lesser of:

- 130% of the Rated Current Consumption of the devices powered by the circuit, or 2 Amps for lower-current circuits;

- The Rated Current Capacity of the smallest connectors or conductors in the circuit.

- Use this document as a guide for continuous current.

- Teams must consider insulation temperature ratings when sizing conductors. Conductors can heat significantly when carrying current due to their finite resistance. Violating a conductor’s Current Capacity can melt the insulation around the conductor or the conductor itself.

- The connections between your battery and any distribution board/panel are a circuit, and must be protected as such. Off-the-shelf battery management systems (BMSs) are allowable here, and are the only exception to the ban on protection systems that rely on software.

- The Interrupt Current Rating of this protection must not exceed the lesser of:

- Ventilation and heat dissipation concerns should be considered when installing power sources, high-current devices, and high-current wiring.

- The ambient temperature outside your Rover will be 40 degrees Celsius.

- The ambient temperature inside your Rover is likely 20C higher than outdoors, depending on cooling strategy, Rover material, paint colour, and other factors.

- Each electronic enclosure should be specified with a maximum internal air temperature.

- The capacity rating of all components in an enclosure should be determined using the maximum internal temperature of the enclosure as the ambient temperature for those components.

- The temperature of each enclosure and high-power component should be monitored, and if it exceeds the maximum temperature, power to that enclosure or component should be shut off.

- Precautions against short circuits and electric shocks must be observed:

- Each battery must be securely mounted to a suitable structural element of the Rover, and should be protected against collisions or rollovers during Rover operation.

- All electrical wiring, connections, and PCB traces must be insulated or taped over to prevent contact with other conductors, Operators, or tools.

- All electrical wiring and connections within the enclosed Rover bodywork must be securely mounted to prevent accidental short circuits.

- Teams must securely mount electrical wiring and connections outside the enclosed Rover bodywork to prevent accidental short circuits or mechanical interference with the terrain if:

- It is safety-critical (e.g., connects to the battery or carries a large current).

- Its upstream circuit protection is also located outside the Rover.

- All electrical connections must be routed away from mechanical pinch points. The full range of motion available to the Rover will be considered when evaluating pinch points.

- Hard stops should be used to limit mechanical movement and reduce pinch points.

- Structural and mechanical elements of the Rover must not be used as part of any electrical circuit.

- All power sources should be disconnected before servicing Rover’s electrical systems.

- All electronics should be housed within a waterproof container or be waterproof themselves.

- Insulation and drainage should be considered.

- Sufficient documentation must be provided to prove the safety of your rover before you will be allowed to compete.

- A block-level schematic must be included in the documentation, and the layout of the schematic circuit diagram should reflect the physical layout of the rover wiring harness, where possible.

- Each power source, circuit protection element, circuit, and device/device group in your documentation on the diagram must be identified and annotated with a short name and rated Supply Current, Current Capacity, Interrupt Current, or Current Consumption.

- Related low-current devices (less than 2A total) on the same circuit may be grouped into black-box subsystems to reduce the complexity of the diagram.

- Evidence of claimed ratings must be provided in the documentation package.

- Acceptable evidence includes datasheets, industry standards, or test reports. Product pages or website screenshots are not acceptable. We will grant exemptions to this requirement on a case-by-case basis for some components when purchased from reputable vendors.

- Components that may be granted an exemption include batteries, battery management systems, and generic connectors (like ring terminals or ferrules).

- CIRC has compiled a list of batteries and BMSs that are trustworthy and may be exempt from this requirement. See Appendix.

- Fuses, switches, relays, or contactors will never be exempt from this requirement.

- Components purchased from Amazon, Temu, AliExpress, or similar retailers will never be granted an exemption to this requirement.

- A photograph or diagram of the emergency stop button mounted on the rover must be included in the documentation package.

- The documentation package must be updated to reflect ongoing changes during CIRC.

- The documentation package, in paper or digital format, must be accessible to judges at all times.

- The documentation package must accompany the Rover to CIRC tasks.

- A block-level schematic must be included in the documentation, and the layout of the schematic circuit diagram should reflect the physical layout of the rover wiring harness, where possible.

- After any safety-impacting changes or safety-related incident, your rover must pass a re-inspection before being allowed to continue competing. The re-inspection will include a discussion of the cause and measures taken to prevent recurrence.

- Safety incidents include, but are not limited to: unprotected shorts, exposed or damaged wiring, battery damage, or any emission of smoke, fire, or sparks.

- A blown fuse or tripped circuit breaker is not a safety incident.

- Non-compliance with this requirement will be subject to penalties under our Code of Conduct, up to and including disqualification.

- Batteries not used in Rovers or equipment that are operating must be stored in the CIRC Central battery storage area or removed from CIRC Central.

- Teams are not allowed to enter the battery storage area.

- Teams wishing to use the storage area must label their battery with their team name and a designated battery number.

- Teams wishing to store or retrieve their batteries must alert the Organizers using the appropriate Discord channel (or alternative communication format if Discord is not used during the competition).

- Organizers will store or retrieve the appropriate batteries as soon as possible. Wait times may reach 30 minutes during busy periods. Plan accordingly.

- Non-compliance with this requirement will be subject to penalties under our Code of Conduct, up to and including disqualification.

- Teams are not allowed to charge batteries inside CIRC Central.

- A designated, sheltered battery charging area will be provided outside CIRC Central.

Appendix: Battery and BMS Suggestions

| Suggested Batteries or Battery Manufacturers | Suggested BMSs or BMS Manufacturers |

|---|---|

| Maxamps | RoboteQ |

| Turnigy | JIKONG |

| GreenBikeKit | Daly |

| Canbat | Canbat |

| Tattu/GensAce | Renology |

| Renology | UBI |

| UBI | Unit Pack Power |

| Unit Pack Power | JK BMS |

| Commercial off-the-shelf drill batteries | BMSs with safety certifications from recognized organizations (e.g., UL, IEC, etc.) |

| Batteries with appropriate, recognized safety certifications such as UL2054, UL1642, IEC62133, UN38.3 etc. |

Changes/Commentary

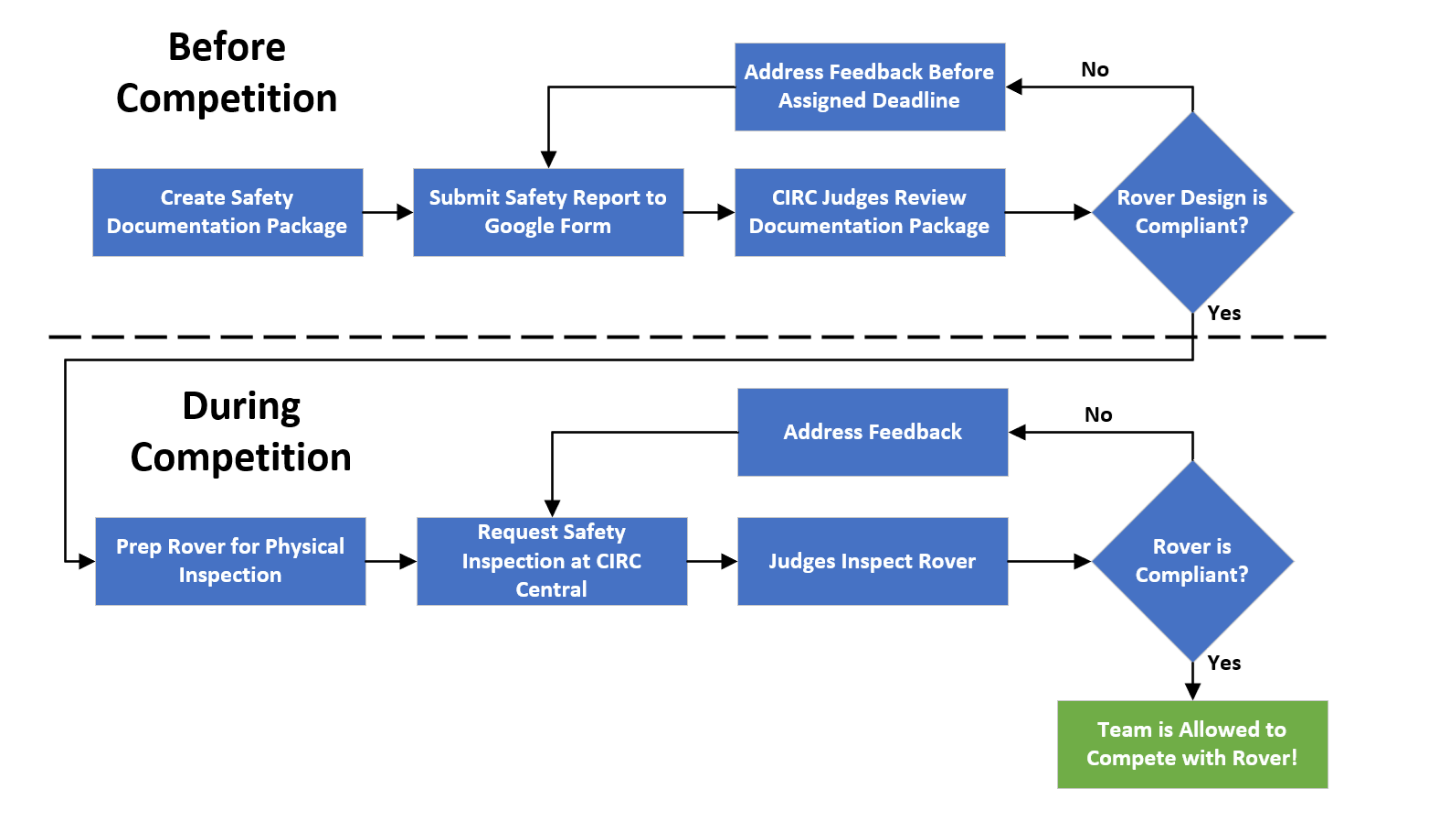

- We outlined the Rover safety inspection process in more detail and provided a flowchart at the top of the page to help new Teams understand how it works.

- We are now conducting spot inspections to ensure that Teams have not made any safety-critical Rover alterations without requesting reinspection.

- We added that kill switches should be illuminated. See 2.11.

- We clarified that BMSs must provide individual cell UVLO. Teams cannot use solutions that only provide UVLO protection to the battery pack output. See Requirement 3.3.

- We banned custom batteries and BMSs (see Requirement 3.7) because ensuring their safety is a significant burden for Judges and Teams, particularly when designs are finalized shortly before the competition. Since overlooking safety-critical aspects of custom batteries and BMSs can be severe, we are not comfortable permitting them for competition use.

- We added that Teams should use LFP batteries, a safer chemistry not prone to thermal runaway. A battery weight bonus system has been developed to incentivize this suggestion. See 3.8.

- We clarified that Teams must consider wire insulation temperature ratings when sizing conductors. See 4.1.2.2.

- We revised requirements 6.2-6.4 to enhance clarity and reflect how we have been evaluating Rover safety in recent years.

- We removed some subrequirements in Requirement 7 as they were mentioned in the Safety Inspection processes at the top of the page. We also reordered the remaining subrequirements for easier understanding.

- We have compiled a list of batteries, BMSs, and their Manufacturers we approved during last year’s competition, as we know choosing batteries and BMSs from reliable sources can be troublesome. See Requirement 7.2.3.

- Due to fire safety restrictions, batteries not used in Rovers or equipment that are operating must be stored in the CIRC Central battery storage room or removed from CIRC Central. Teams may request Organizers to store their batteries in a dedicated battery storage room within CIRC Central. See Requirement 9.

- Due to fire safety restrictions, Teams cannot charge their batteries in CIRC Central. We will provide a sheltered space for Teams to charge their batteries outside of CIRC Central. See Requirement 10.

Change Log

| Date | Change Note |

|---|---|

| 2026-09-30 | Initial Publication |